Part 4

Article By: Tyler Ludlow

Originally Published In The December 2014 Issue Of Cycle Source Magazine

Any biker knows that problems on the road should be accounted for and expected. Reality is not like Vimeo music videos about motorcycles trips: Your new Craigslist carburetors run great. It never rains. Gas stations are always open, and your twenty-something girlfriend already French-pressed the coffee when you wake up at camp— completely refreshed. Small business owners and motorcycle builders do not have it any different, and the problems can be twice as bad when you are both. Shit can hit the fan, and the fan might still be dirty from the last time. Come to think of it, that fan might’ve been stinky when you bought it. This is what happened to Paul Wideman. Paul is currently making someone’s dream come true with this J&P Cycles A “Heartland Hustle” Giveaway Bike, but he needs to have a business to come back to when that lucky bastard rides off into the sunset. When a broken shop machine also birthed a broken repairman, Paul realized he would need downtime to fix it himself. Therefore, in this issue, instead of seeing how the roller comes together , let’s look at how the pieces come apart. Jeff Bailey , Engineering Manager of S&S added some interesting history to the build.

“It was always meant to be a custom application, beginning in 2003 and took five years to develop. We worked with Sam and “Skeeter” Todd from Rolling Thunder to create a transmission case to be used in rubber mounted frames, but really there is no stock frame to be used with the X-Wedge. The biggest outlets were originally Big Dog, American Iron Horse, etc., but actually the biggest users right now are the Morgan three-wheeled cars in Britain. They’re classified as motorcycles.” It would be unusual to see the 117” X-Wedge next to you at a red light. The X-Wedge’s machinery had been moved to the UK manufacturing branch, but the US market has already learned lots from the design. “The triple cam (one intake, two exhaust) and other aspects are something you’ll see are similar to new Indians manufactured in the US right now. The Twin Cam also uses the Easy Start 548 cam, allowing for mechanical release of pressure between starting the engine and idling,” Jeff revealed. Before the roller had even come into the Bare Knuckle shop, major alterations had been done. The team at Rolling Thunder had already answered J&P’s call for an X-Wedge power plant in FXR packaging –but there is more history in the frame than the X-Wedge and S&S transmission let on. Sam Pileggi took me on a short verbal tour of their manufacturing processes.

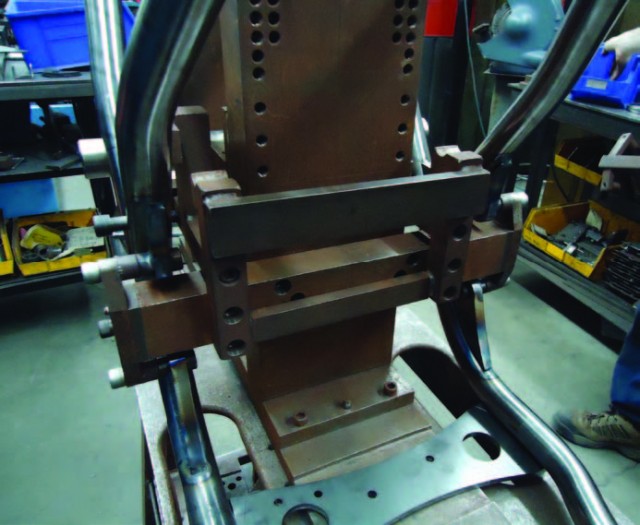

“All of our frames start with TIG welded DOM 120 ball steel, but the important part of our business is creating a style for the customers needs, and not just letting them know what parts they can use. I’m not a fan of telling someone what he or she is allowed have on their dream bike,” Sam reminded. The X-Wedge engine was designed for custom applications, but was made compatible with Evolution and Twin Cam bolt pattern primary drives. Making it compatible with a rubber engine mounts on the FXR frame required a 2-inch stretch in addition to adding the mount pattern. The Rivera Primo Brute 4 Extreme was chosen as the primary, introduced by Ben Kudon of Rivera Primo. Ben identified the exact model by glancing at the pictures in Cycle Source vol.18 issue. 7, like a musician hearing his own music. “Yes, the Brute 4 Extreme has the same bolt patterns as early Evos and Twin Cams taking it from 11.323 to 12.812 inches, so it is a little wider, but the belt is still three inches. The 66 tooth ring gear will handle in excess of 150 horsepower, so it’s a great choice for the X-Wedge. One feature we wanted in this model was to put a threaded hole and including a nipple in the primary kit so you can run an oil filter and lines completely hidden under and behind the plate. It looks great. We also added the option of mid controls.” Fans of Bare Knuckle Choppers are not surprised to see the open primary, but the performance of the bike is an even higher priority than the looks. “When you get a big engine like that, the quality of the clutch gets to be very important,” Ben explained.

“We use diaphragm springs instead of coil springs in all of our clutches, because they create even pressure on the plate. This may seem like a minor thing, but moving the plate as a whole removes lots of tension from the clutch hand. For other clutches, people try to reduce tension by removing any of the ten coil springs. This can allow it to slip, and as you know, cause real problems.” Ben also lent a heartfelt sentiment that anyone about to build their motorcycle should hear. “We’re believers in the “kit” idea, and our products come with everything you need to install with standard tools. I’d say our customers flow uphill- with garage builders/end users in mind, professionals are also attracted to the ease of the install. Quality comes at a cost, its not cheap. There are lots of manufacturers screaming about Made in America, but sometimes they’re just slapping stickers on brown Chinese boxes. If your model is to replace something when it arrives broken, that’s not the way to sell stuff. That’s not how we sell things overseas and represent our country.” We are sure that Paul can appreciate suppliers he can count on when he opens his toolbox.