Published In The August 2015 Issue Of Cycle Source

Article & Photos By: Daniel Donnley www.pamdemoniumcustomchoppers.com

TheHigh Life Project came back into the shop over the winter to have the electric foot installed and we are at the end of May and here In Defiance Ohio we have only had 2 weeks to our riding season so far and the shop being as busy as it has been I haven’t been able to get The High life project out on the road for test miles.

I got a call one day from Duke, asking if his little chopper was ready and I told him it had been ready for months but I just hadn’t had time to ride it because of the weather. He really wanted to ride the chopper this summer but I told him I had to put a few miles on it to make sure it was 100% for him. Duke agreed to let me keep it longer and told me to make sure I tested it and that it worked good.

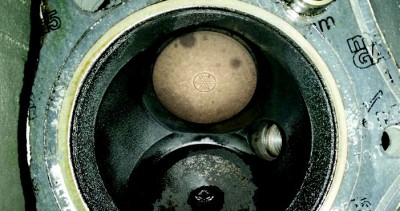

So with a break in my schedule and a sunny day I took the little chopper out for some test miles and it did really well. But with pressing work back at the shop I had to cut the ride short and get my ass back to work. A few days later with a gap in my day and a little free time I took it out again for another test ride, after getting ready to put a cap on a 100 mile ride I kept hearing Duke’s voice in my head saying “You got to test it to make sure it’s good”. At this point I had just been riding the bike like you normally would. I rolled up to a stop light as I am sitting there a shiny new V-Rod pulled up beside me, I looked over at the guy for a minute and he just stared straight ahead and wouldn’t even say hi like most people do. But something told me it was time to “Test It”. With a quick look from the guy on the V-Rod I knew it was game on. I told myself, I know my backs against the wall with this V-Rod but I’m gonna give it all the fury this chopper has got on this V-Rod. So the light turned green and with a whole handful of throttle she was off like a rocket ship. I kept glancing out the side of my helmet and there was no V-Rod to be found. I was ringing it out for all it was worth. I stabbed second gear and all hell broke loose. It’s like the little chopper fell flat on its face and I knew something immediately bad happened. So all I can think is F#@k, I pulled off the side of the road and it stalled. I got off the bike and gave it a once over and didn’t see any holes or puddles of oil. So I fired it back up. The damn thing sounded like a hit and miss engine, it was running on one cylinder. I chitty, chitty bang banged it all the way back to the shop. Once I got there I shut the bike down and pulled both plugs and immediately ran a compression test. The first one I checked obviously got me home because it was good. The other one was obviously the one that the chitty, chitty, bang, bang was coming from. It didn’t have enough compression to even think about running. Mind you, the f#@ked up part about all of this is that Duke is coming to get his bike in 3 days. But…my dumb drag racing ass blew his bike up. With it already being late into the evening I decided I would tackle it first thing in the morning and decided it was time for some brews and a good night’s sleep. I knew the next day I was going to have to pull a Hail Mary out of my ass to get this going. I woke up the next morning bright and early and with coffee in hand it was time to go after this chopper and see what was going on. In a few short hours I had the engine torn down and on the work bench. That is when I discovered that the cam shaft was broke in half. I about shit. But I knew I had another one on the shelf that was for my engine build, so far so good. Thinking that some bent valves also might be part of this equation. I made a quick phone call to the Hart’s machine shop in Cecil Ohio to ask if they could check this cylinder head out for me. They told me to get it over there as soon as possible. By this time it was already 2 in the afternoon. So I jumped in the “Pan” van and headed for Hart’s, hoping the whole time that I didn’t bend any valves because I didn’t have any spares. When I walked in the door at Hart’s they were slammed ass busy as always, Jimmy Schindler saw me walk in and said, “Hey man come on back.” He literally dropped what he was doing just to check out my cylinder head. I wasn’t there for even 45 minutes before Jimmy had it disassembled, checked out, back together and sending me on my way back to the shop. With a good bill of health on my cylinder head, and since everything has checked out good, it was now time to get this new cam shaft in, degree it and reassembled. It is now about

Compression Test done—–Well here is the problem!

Started disassembling the engine and look at what I found! Holy Batman! The cam is broke in half! Well now I have a $400 paper weight!

Questionable cylinder head…Thanks Hart’s Machine for the top notch service!

Inspecting for carnage!!

8 at night. I had the bike all back together and running by 10pm, 3 heat cycles later and a cylinder head re-torque, by 2 in the morning. Time to get some grub and hit the sack to hopefully take this little chopper out for a test ride in the morning. Moral to the story, next time you’re in a situation that you think you need to give it just a little bit more and “Test” It, let me make a suggestion… Don’t…Because if I didn’t have the parts and a super stand up machine shop this bike would have been down for easily over a month.

At Hart’s machine shop getting the cylinder head valves touched up!

Some…assembly required, Not like the bike needed more power but I advanced the new cam 3 degrees for more midrange power.

All buttoned up, putting on a fresh tune.

If you have any questions please feel free to call me at the shop anytime 419-576- 6812 – Daniel Donley

Resource: Hart’s Machine Service Inc. 106 North Main St Cecil, OH 45821 419-399-4777